Design and Finite Element Analysis of 12-Speed Gearbox

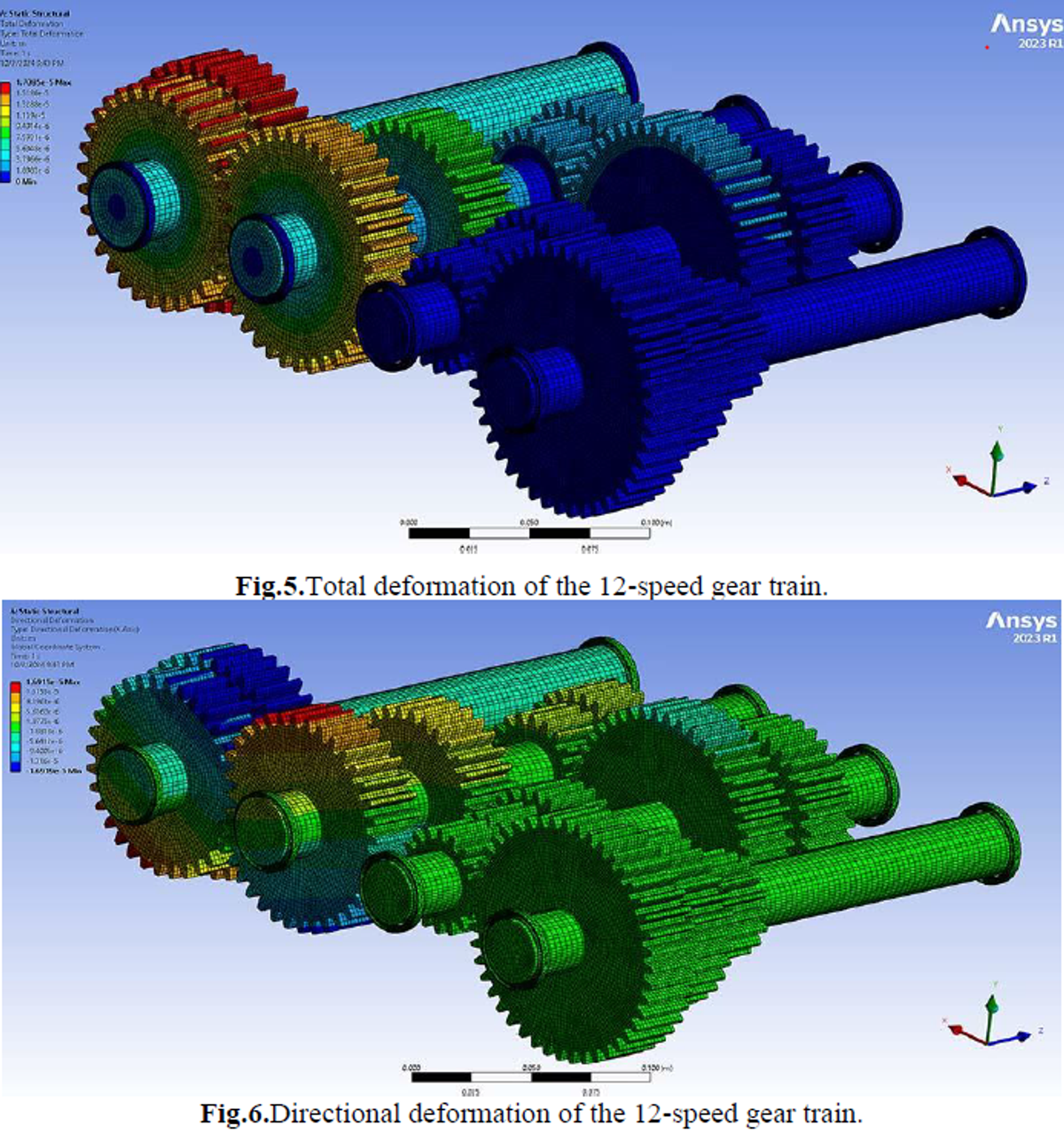

This research presents an in-depth examination of a 12-speed gear train system, focusing on the mechanical properties and performance of components fabricated from alloy steel (maraging 300) for the spur gears and annealed carbon steel (1095) for the shafts. The investigation utilizes finite element analysis (FEA) to examine essential factors including gear deformation, stress distribution, and gear teeth critical locations. The results indicate a minimal total deformation of 1.7085e-5m and a maximum principal stress of 2.0395e+8Pa when subjected to the applied torque, highlighting the system's stability and structural integrity during operational conditions. The selected material properties for fabricating the 12-speed gear train exhibited significant resilience and suitability for load-bearing applications. To further improve, the research investigates essential performance factors such as gear speed, load, torque, mesh stiffness, and gear tooth contact stress, offering significant insights for the optimization of gear design and the improvement of performance in diverse industrial applications.